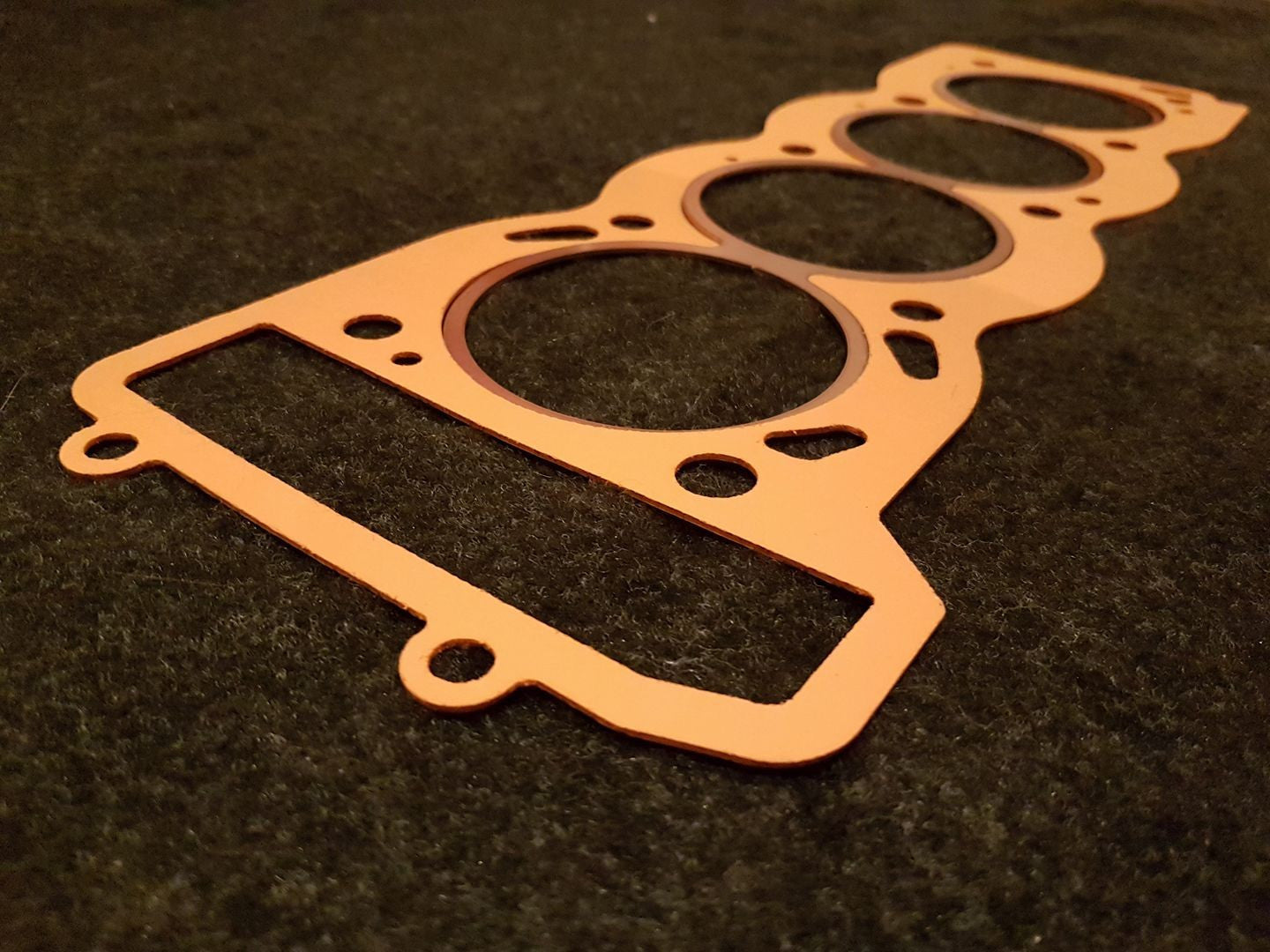

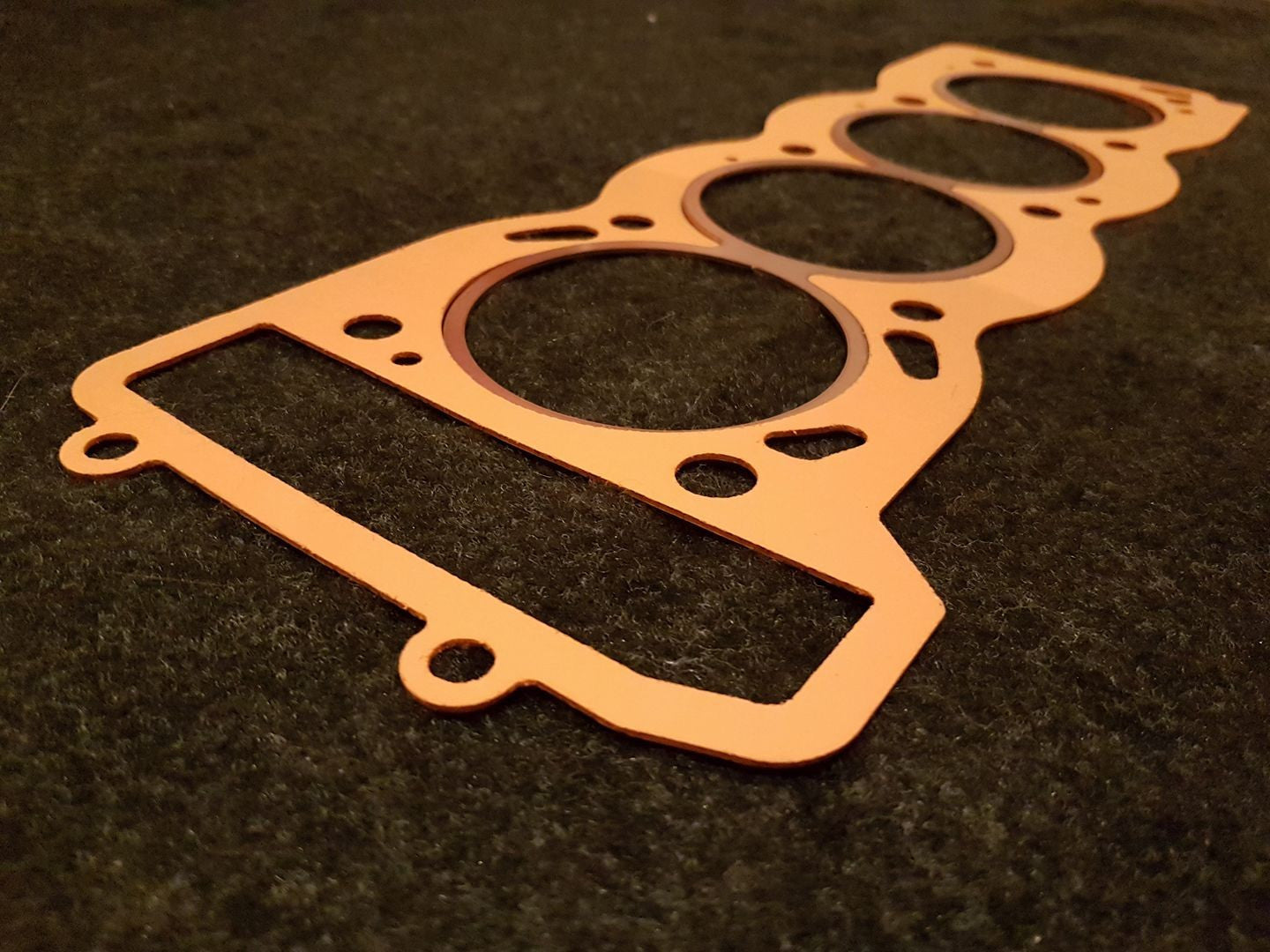

Designed for high out put applications where much higher cylinder combustion pressures are present

Malleable:

Copper is stronger than any composite head gasket yet still malleable so it conforms to the sealing surfaces. This strength-malleability combination is, more than any other attribute, the advantage of copper as a head gasket material over other materials. While the advantages of strength are self evident, the benefits of a malleable gasket body are somewhat more distinct. Conformity makes a tighter seal which will show up in lower leak down percentages.

Conductivity:

Copper is the standard for conductors. Superior conductivity benefits performance and racing engine builders in two primary ways:

A. block & head temperatures are more even.

B. Combustion chamber hot spots are dissipated quickly. Cylinder block/head temperature parity is an aid to tuning, though frankly, it’s a minimal factor until you reach the narrow end of the tuning window. The big advantage of conductivity is in the combustion chamber area. In and around the combustion chamber standard composite head gaskets and MLS head gaskets are somewhat insulated from the cylinder head and block by the facings and coatings respectively. Heat related failures occur more often with composite and MLS head gaskets than with copper because the heat is trapped within the gasket body allowing hot spots to intensify, whereas the copper being both a better conductor and having direct contact with the block and head (remember metal-to-metal) transfers the heat to the heat exchanger, aka the cooling system, through the head and block

Elasticity:

Another interesting feature of copper, this benefit comes into play when you’re out of the tuning window far enough to actually damage the head gasket. Un-alloyed or pure copper has a 25% coefficient of elasticity; cool term, here’s what it means. In a 4 inch section, the copper head gasket will stretch to 5 inches before it ruptures. This gives the user a ‘safety factor’ not available with other head gasket materials

Fitting:

Block and Head surfaces should be within .002” across and .004” lengthwise, with surface finish of 60 to 80RA preferred, 60 to 100RA acceptable

No re-torque required

Head gaskets for oversize pistons, please see our solid copper head gaskets

https://trusttubular.com/products/saab-900-9-3-9-5-9000-high-performance-solid-copper-head-gasket-1?_pos=1&_psq=head&_ss=e&_v=1.0